Extreme Crosman Modifications

.50 Cal Muzzle/Breech Loader

Want to really tear up some cans? With about $10 worth of parts from the hardware store, you can make a powerful short range gun that can be used as a .50 cal rifle or shotgun. It works great for killing large pests around the house at close ranges, and loaded with #6 shot, it will tear sparrows to shreds.

Parts Needed

You'll want to pickup a good length of type K or L copper pipe from your local hardware store. While you are there, get a copper end cap for the muzzleloading version, or get a 1/2" copper to 1/2" NPT adaptor and 1/2" NPT end cap for the breech loading version. You'll also want some silver solder, a propane torch, and a couple of hose clamps. Pick up a length of steel brake line from your friendly auto parts store, and you're all set.

Transfer Port Setup

Use the picture below as a reference:

You'll want to remove everything from the gas tube as you construct the transfer port. Failure to do so will melt the seals in the valve, rendering it useless. Drill out the original transfer port hole to tightly fit a length of steel brake line. Sand the gas tube down to bare metal around the enlarged hole. Cut a 1/4" length of steel brake line and sand it as well. Place the piece of steel brake line into the gas tube, making sure that there is plenty of clearance for the valve. Apply flux and silver solder the two pieces together.

Constructing the barrel

Use the picture below as a reference:

The main catch to the barrel assembly is to cut the barrel long enough to clear the rear of the gas tube. If you neglect to do so, the endcap will raise the rear of the barrel, causing gas leaks and making the gun shoot low. BTW, the above picture is of the muzzleloading version. Stand by for the breech loading version which is currently under construction. To give you an idea of what the breech loading version should look like, go over to the homemade airgun section.

Drill a hole in the barrel to accept the transfer port, making certain that the endcap of the barrel will clear the rear of the gas tube. At this time, you will want to silver solder in the endcap or breech assembly. Make sure that the pipe is sufficiently sanded and fluxed. This bond is very critical, since you dont want to wear this part of the gun in your head! If you are building the muzzleloading version, an important safety mod would be to drill a hole all the way through the cap and barrel and secure it with a nut and bolt.

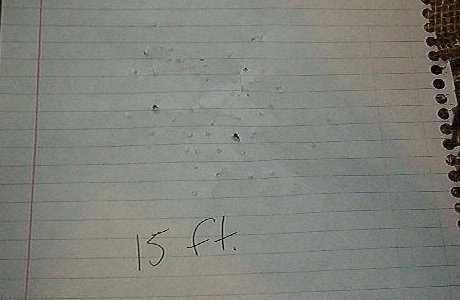

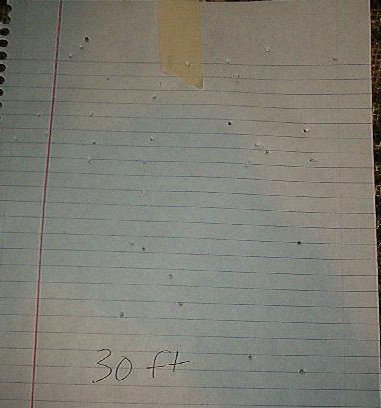

Shot Patterns

Here is what this gun can do with #6 shot at 15 ft and 30 ft:

|

| Home |

| Blowguns |

| Crosman Mods |

| Forum |

| Homemade Airguns |

| Hunting with Airguns |

| Links |

| Photo Gallery |

| Airguns for Sale |

|